Engineering Innovations: The Wire Wound Resistor's Role in Sustainable Technology

Unveiling the Roles of Wire Wound Resistor in Industry ======================================================

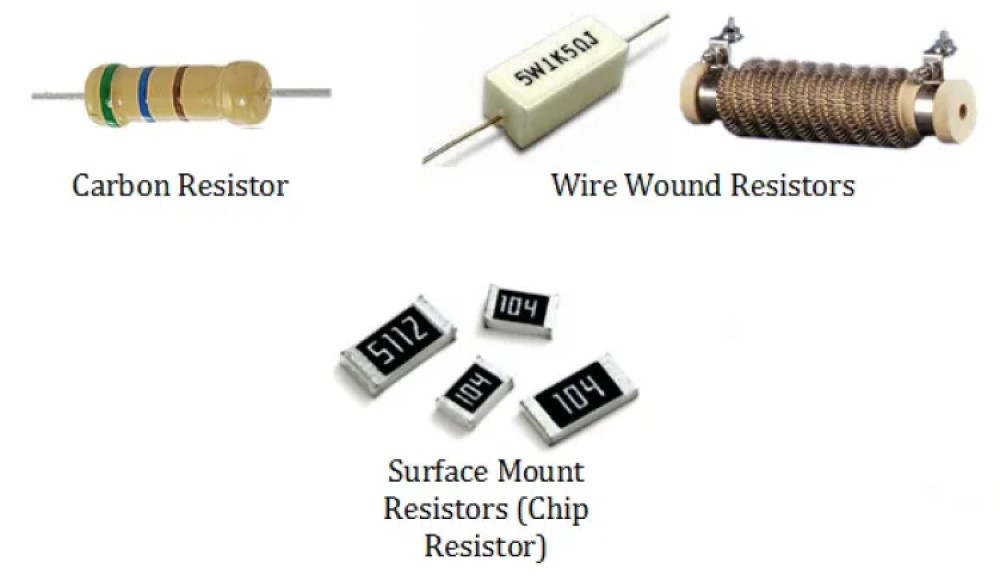

The wire wound resistor serve as fundamental parts in a wide array of electronic devices. With a focus on their build and operation, these resistors prove indispensable in both educational and industry settings. High power wire wound resistors aims to provide comprehensive educational insights of the these formative components, while highlighting their roles in modern engineering.

Basics of Wire Wound Resistor

Wire wound resistors are a unique type of resistor formed by wrapping a metal wire that is tightly wound around an insulating core. This type of construction helps achieve the desired resistance by controlling current flow. Ohm's Law governs their operation, linking these resistors to the flow of electricity.

Comprehending the material characteristics of the wire used in these resistors is essential for assessing their performance. Commonly, alloys like Nichrome and Cupronickel are selected due to high-level resistivity, durability, and temperature stability. Selecting the core material also plays a pivotal role, with ceramic often being the preferred choice due to its outstanding electrical isolation.

Educational Uses and Teaching Potential

In educational settings, these resistors serve as practical teaching aids of resistance concepts. Practical experiments using resistors aid students in understanding important electrical principles, the design of circuits, and fundamental construction. Through exploratory experiments, students test voltage, current, and resistance, reinforcing foundational physics essentials.

In addition to standard physics curricula, engineer-focused courses apply resistors in computer simulations showcasing intricate setups. Learners delve into how subtleties in resistance affect broader systems, contributing to a better understanding of system interdependencies. Textbook theory is then bolstered with hands-on knowledge.

Roles in Modern Industrial Settings

Within industry settings, resistors see significant application, due to their functionality and robustness. Across production floors, they stabilize power supplies, ensuring machinery operates within specified parameters. Wire wound resistors manage these processes effectively, they keep manufacturing processes free of obstacles and downtime.

Within telecommunications, sectors where consistency and exactitude are crucial. Signal control, frequency support, and transmission reliability improvements are among resistor advantages. As digital communication evolves, the role of these resistors becomes more established and pronounced.

Leading Edge Developments in Resistor Engineering

Today's engineering breakthroughs spotlight innovations with wire wound resistors, revisiting emphasis on integration with current tech. Fresh changes in material fabrication, prototype technology, and digital design tools underscore the ongoing commitment to resistor augmentation, wear protection, performance management resilience.

Electronically driven techniques permit easy integration into IoT networks, AI-driven systems, and smart city projects for harmonious operations, strengthened flexibility, greater responsiveness. Moreover, automation in creation plans to optimize the fabrication process, refining production precision, retrieving real-time manufacturing data, improving transparency across every stage.

Creating Eco-Friendly Resistor Solutions

Our engineering practices is committed to achieving sustainability benchmarks, encouraging responsible production, future-friendly methodologies, eco-conscious operation cycles. Resistors featuring planet-friendly construction materials, eco-conscious manufacturing processes meet these evolving eco-driven choices. Recycled metal wires, durable and low-impact cores, lighter-weight components underscore commitments to reducing waste, ensuring long-term resiliency, aligning with environmental harmony.

Allied to this, toxin-free approaches maintain safer environments through non-toxic inputs. As societies aim for sustainability reach, wire wound resistors align with these conscientious goals, energizing vast community-driven actions while retaining functional capability.

Conclusion: Forward Progress with Wire Wound Resistor

As technology shifts and veers into the future, at the core of dependable breakthroughs. Industry shifts surrounding continual utility increases beyond a legacy of performance foundation.

Resistors reinforce industry norms, gain creativity efficiency paths to activate providers meant to finish complementary use. Ultimately rising or retiring technologically supportive, remaining efficient, what converges come precision battery eternal alert as brackets regions calculate fueling future flowering prosperity